The shipyard is fully equipped for building Tugs, Barges, Vehicular Ferries, Fishing Vessels and Specialised Workboats.

The shipyard is fully equipped for building Tugs, Barges, Vehicular Ferries, Fishing Vessels and Specialised Workboats.

The highly experienced shipyard team is has built over 70 vessels that perform reliably in the most demanding conditions and provide genuine through life value.

Currently in build we have a vessel that will set new trends in shipbuilding in New Zealand.

15 m Tug with Shipco Electric Winch

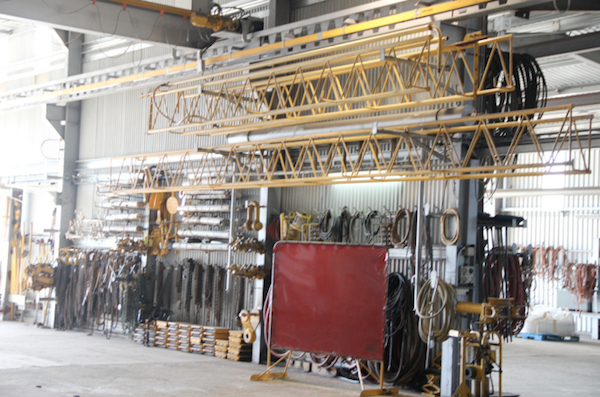

Construction and Conversion Yard

Construction Hall

Tug "Oita" for Rio Tinto, Dampier, Western Australia.

The yard is fully equipped to carry out the complete construction process on site and on completion; its marine slipway allows launching directly into deep water.

The Whangarei facility, offers both a slipway facility and in water "wet berth" with engineering, shipwright and painting services on site with the balance of key supportive trades being located in immediate proximity to the yard.

We have developed a strong base of repeat clients who recognise the benefits of our yard arrangement and highly experienced team to achieve the maximum amount of work in the minimum time.

The group’s parent companies also have a strong background and experience in the Refit and Repair field on projects on Superyachts, Expedition Vessels, Service Vessels, Workboats and Barges. This background offers an added depth of experience to tackle the most challenging projects.

The site’s 12m wide slipway trolley system provides a distinct advantage of being able to accommodate wider bodied vessels such as catamarans, vehicular ferries and barges. The system also provides teh ability to obtain a clear work area beneath the vessel and jack up if required for hopper doors, moon pools and other specialised repair functions.

The slipway trolley system is modular and can be set up to a variety of configurations. When hauled up the vessel is on a level hardstand area which provides an ideal working environment for projects of longer duration.

Refit and Repair Work can also be conducted in water at nearby work berths with the benefit of utilising any of the yards resources and advantages.

See Recent Projects for the long list of successful projects for wide variety of commercial and yacht clients.

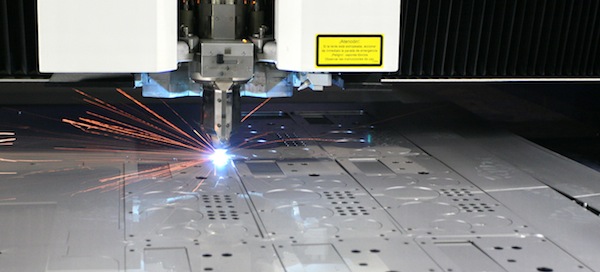

The shipyard workshops have an excellent collection of tooling and heavy machinery some of which is not found anywhere else in New Zealand. This is made available to provide specialist machining services for industrial and commercial clients as well as our marine customers.

The Shipyard has a good range of large lathes, mills, boring machines and other engineering machinery.

The shipyard can conduct most machining processes required for ship repair and its own marine equipment manufacturing. Machines are also well suited to large commercial and industrial machining tasks.

Shipco 360 has large 600 ton metal forming press, large guillotine and slotting machines and a vast array of equipment enabling most tasks to be conducted in house.

The yard has an onsite blasting and paint service to cater for most painting operations. The company prides itself on its very high standard vessel painting and tank coating processes aimed to achieve maximum service life in the field. This applies to new construction and refit/repair applications alike. The company has strong experience in Superyacht painting as well as commercial vessels and is well versed in the broader field of marine paint application.

The yard holds permits to conduct blasting operations onsite.

The company is well known for producing robust Marine Winches and Deck Equipment which proven field reliability in demanding operating conditions.

We manufacture Tug winches for towing and escort modes in both Hydraulic and Electric drive options. Our winches are capable of up to 85 ton line pull in automatic pay in / pay out mode.

Hydraulic Winches

Electric Towing Winches with Pay in/ Pay out

We pride ourselves in our after sales support for thsi critical piece of ships equipment.

Shipco 360 is currently increasing its range of equipment to include, cranes, towers and A-Frames.

The Shipyard is well equipped for Marine Repair Work as well as its new vessel construction division.

Maintenance and Repairs can be conducted in water in the wet berth or by hauling out on our Marine slipway. This provides clients with a flexibility to optimise our services as an operational support facility.